Χωρίς κατηγορία

The Difference Between AC and EC Fans

Magnetism – the fundamental principle in every fan’s operation!

When installing an electric motor, the device converts electrical energy into mechanical energy through rotation. Electrical power is mainly measured in kilowatts (kW), while mechanical rotation is measured in rpm (revolutions per minute). However, part of the electrical energy is lost during operation due to friction and other inefficiencies. Motor efficiency is indicated by the symbol η and expressed as a percentage. It usually reaches up to 85%, meaning about 15% of the energy is lost. The higher the efficiency, the fewer the losses and the more energy is converted into torque, which is measured in Nm (Newton meters).

The electric motor operates based on the interaction of magnetic fields. When current is applied to the stator, a magnetic field is generated, which interacts with the rotor magnets, causing it to rotate. The stator is the stationary part of the motor, while the rotor is the moving part, onto which the shaft is mounted. The fan blades are attached to this shaft. The magnetic field in the stator is created by coils using alternating current (AC).

Types of AC Motors

Asynchronous and Synchronous

In the HVAC market, AC motors dominate due to their reliability and easy maintenance. They are divided into two types:

-

Synchronous motors: The rotor consists of permanent magnets and follows the rotating field of the stator synchronously.

-

Asynchronous (induction) motors: The rotor does not contain magnets but conductive bars made of aluminum or copper. Current is induced according to Faraday’s law, creating torque that rotates the motor.

In asynchronous motors, the rotational speed is always slightly lower than the field speed – this is called “slip.” The greater the load, the greater the slip, and thus the induced torque.

Speed Controllers for AC Motors

Synchronous motors mainly work with frequency converters (inverters), while asynchronous motors can operate with either inverters or simple speed controllers.

Inverter (frequency converter)

Uses PWM (Pulse Width Modulation) technology and IGBT transistors for precise frequency and voltage control. It ensures high energy efficiency but is more expensive and complex to install.

Voltage controller

A more economical and simple solution but only reduces voltage – not frequency. It is suitable for applications where torque decreases with speed. It operates without adjustment after installation. The most common technologies are:

-

Transformer regulators (multi-stage)

-

Electronic TRIAC regulators

EC Motors – The New Generation

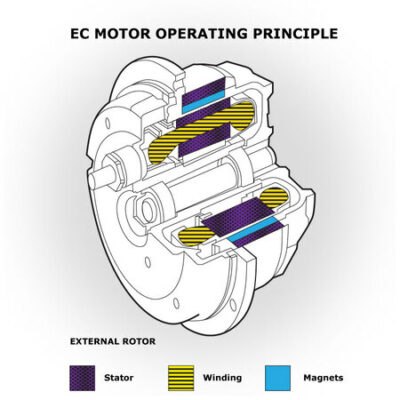

EC motors (Electronically Commutated Motors) are synchronous motors with an integrated speed controller, powered by AC but operating with DC via an internal converter.

The rotor contains permanent magnets and rotates with the help of the stator’s magnetic fields. The position of the magnets is detected by Hall sensors, allowing precise and smooth control of torque and speed.

Advantages of EC motors:

-

Integrated speed controller

-

Lower energy consumption

-

Higher efficiency and stability

-

Communication capability via Modbus

-

Ideal for BMS (Building Management Systems) and “smart” ventilation systems

Although the cost of an EC motor is higher, it provides longer lifespan and energy savings, making it ideal for modern applications.